Pathways: Profiles of Local Food Systems Changemakers

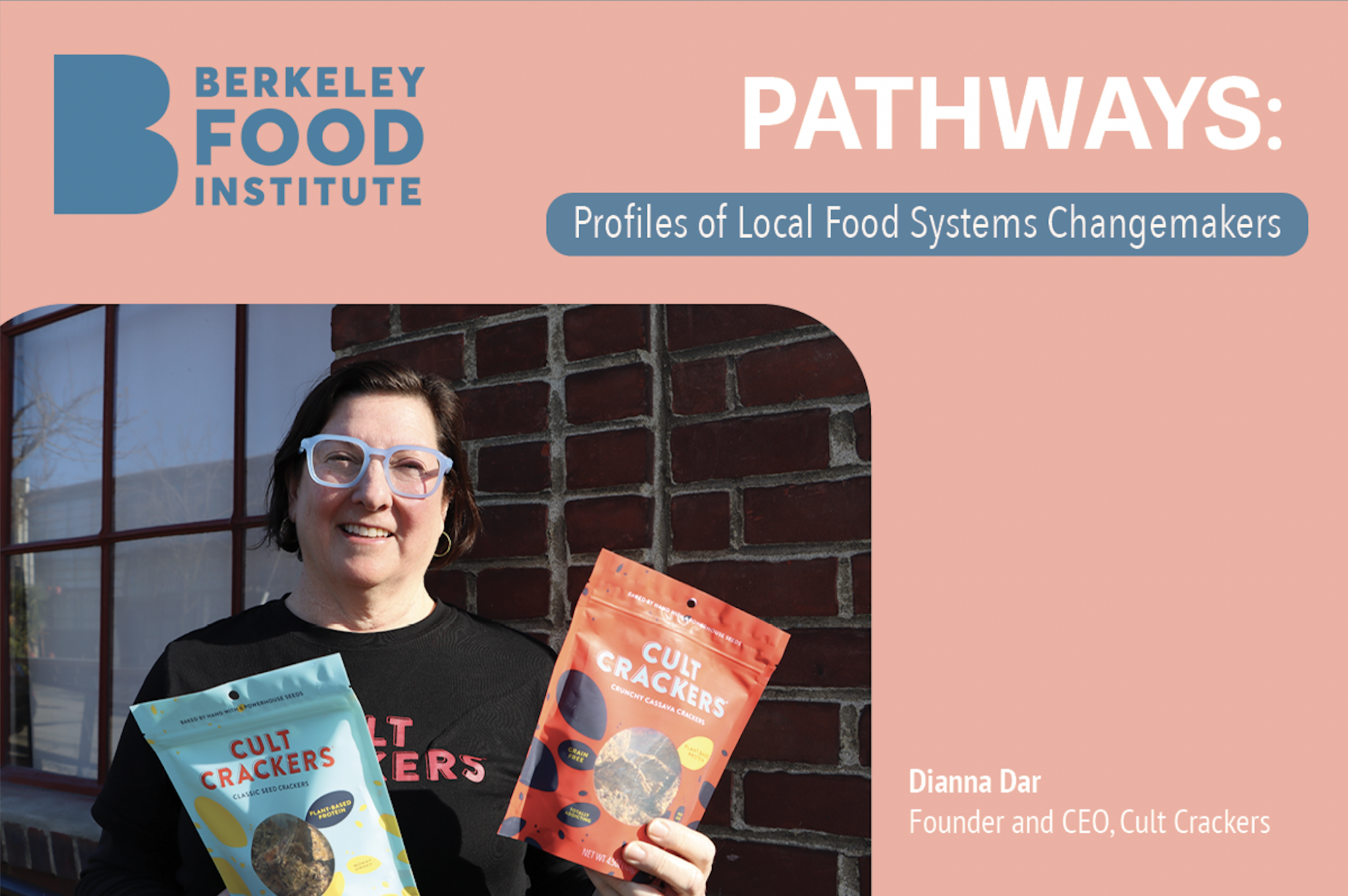

Dianna Dar, Founder and CEO, Cult Crackers

The West Berkeley based food manufacturer gives us a behind-the-crunch look at her small food business.

This is the third profile in a storytelling series called “Pathways: Profiles of Local Food Systems Changemakers.”

One afternoon in March, we pulled up to the Berkeley Kitchens, a shared-use commercial kitchen in a redbrick building in West Berkeley. Dianna Dar, the founder and CEO of Cult Crackers, greeted us with a smile and welcomed us into the collection of small shops, bakeries, and kitchens that fill what was once an industrial factory.

Dianna took us through the building, knocking on doors and introducing us to her neighbors who run other bakery and food businesses, like Third Culture Bakery and Standard Fair, who let us peek into their kitchen operations as they packed up for the end of the day. The Cult Crackers kitchen space was a bright lofted room, not much larger than your average college apartment. Dianna walked us through every step of the process — all of which is completed in house — from receiving ingredients and baking to packaging and shipping. Many of her tools, like her cracker slicer, are one-of-a-kind — built and designed by Dianna and her husband specifically for Cult Crackers.

Once we got the lay of the land, we sat down for a deeper discussion on Dianna’s personal and business story, and the crunch behind Cult Crackers.

This interview has been edited for length and clarity.

You’ve had an interesting career path — from studying at UC Berkeley and culinary school to a career in marketing. Where did your interest in running a food business begin?

Dar: I come from a farming family. My grandfather farmed, my father farms, and my brother now farms. I grew up in the Central Valley and Coachella Valley around produce — fresh fruits and vegetables. That background has given me an awareness of whole foods and using real food — my product has nine ingredients. We just keep it real food and real ingredients. That’s the way I eat and that’s the way I cook. Between the marketing background, culinary school, and baking for a couple years in restaurants, the combination of those really helped me with the skills I needed to start a food business. I don’t have a business background, so I’m learning that as I go.

What was the process of starting a small food business?

Starting out, I didn’t know what I didn’t know. As I mentioned, I don’t have a business background. But I’d say, it’s not rocket science but a lot of common sense. You need to develop trust with the retailers, your buyers, that you have a good product that is going to taste good. But it goes beyond just taste. It’s your packaging. It’s your marketing. It’s your dependability. If you say you’re going to deliver, are you going to deliver? Are you going to run out? Can you keep up with the demand? So I just made sure I was as professional and buttoned up as I could be to earn their trust.

Now that I’m seven years in, it’s a lot easier getting Cult Crackers into stores because I have a track record. But those first few stores were more challenging. The first one was a small cheese shop, and then Berkeley Bowl. Once other retailers see that other stores have taken you in and that you’re established, it gets a little easier.

What is the community at the Berkeley Kitchens like? Is there any resource sharing between the other tenants?

Yes, there are. With my next door neighbor, Jen from Better Bakery and Mesquite Provisions, we share a lot of information resources. I just got some samples of cinnamon from a vendor that I’m not going to use, so I gave the cinnamon to her. We also share ingredient sourcing. If somebody’s out of something, we are happy to share.

We know obtaining organic certification can be a long and costly process. Can you tell us about your experience with organic certification and what it means to be an organic food manufacturer?

Being certified involves a lot of documenting — everything that comes in the kitchen has to be documented and everything that goes out has to be documented. I trace where everything came from, what I paid, who delivered it, and which batch numbers it was in. Once a year, an inspector visits and they’ll pick an ingredient and I’ll have a trace back to where I got it. When did it arrive? Who delivered it? Which batch numbers it’s in and where those batch numbers went. It’s a lot of documentation. And I’m proud that I’m certified organic. In order to be able to say organic with CCOF, you must be 92% organic. So everything here is organic except the Himalayan salt.

What are your relationships like with suppliers and buyers?

With the ingredient suppliers, they have to be organic and they have to be gluten free. So we’re always checking on the suppliers’ certifications because we need to submit those for our organic certification. Sometimes we have people who find us or we find them, it goes both ways. Most of the suppliers have warehouses in the Bay Area, so it’s easy to transport. Cassava flour comes from the east coast, so the freight on that is expensive. I’m always trying to source new ingredients. I’m always trying new ingredients and doing test batches with the new ingredients.

My favorite part is the relationship with the buyers. I still make my own deliveries in Berkeley. This morning, I delivered to Berkeley Bowl and Berkeley Natural. On my way home, I’ll probably make a delivery. I sell to the stores that I shop at.

How do you balance your cost of doing business with providing employees a livable wage and benefits as a small business?

I treat my employees the way I want to be treated. To me, that means paying them a living wage, paying them sick leave, giving them paid time off, and offering benefits. It is really important to me that we offer medical and dental sick leave. I really encourage them to take it. I sent somebody home today who wasn’t feeling well. They’re here every day; baking, packaging, and working hard. That’s why I want to make sure they’re paid well and taken care of.

I have hired refugees. You don’t need to speak English really to work here because you are baking and packaging. I can work around that. I have unhoused people working for me. I have Berkeley High students. I’ll try to give anybody a chance as long as they want to work hard.

What is your advice for people who want to open their own values based food business? What skills do you recommend aspiring food business owners should focus on?

DA business background and business classes help. I could have used that early on. I’m currently doing the 10,000 Small Businesses program through Goldman Sachs, which has been an intense 15 to 20 hours a week but has helped me learn the business side of things like how to closely read my profit, loss, and balance sheets. By the end of the program, I will have a five year strategic growth plan.

You also have to be creative and find different ways of thinking and running your business. When I was just getting started, I wasn’t using the kitchen space seven days a week because I didn’t have that many buyers, so I subleased the kitchen space to a bigger brand and they used it four days a week. I call them our angel investors because they helped subsidize us the first year.

And finally, stay true to your values. What’s important to you? Whether it’s organic, sourcing locally, using sustainable packaging, or whatever you believe in — stick to that as your north star, and it makes it easier to run your business. Be persistent, be kind. That goes a long way.

“Pathways: Profiles of Local Food Systems Changemakers” is a project of BFI’s Food Systems Career Development Program, funded in part by the USDA Transition to Organic Partnership Program (TOPP). Aligned with TOPP, BFI focuses on workforce development in the areas of values-based supply chains and technical assistance for farmers in the organic industry.